-

Request a quote

Request a quote -

Resource Library

Resource Library -

Micron size guide

Micron size guideApplication Recommended

Sizing ( microns)Comments Cooling Tower Bleed-off / Blowd 5-55 Closed loop filtration 5-55 Tower Basin Cleaning / Sweeper Jet 5-55 Cartridge replacement 2-55 Protection of Heat exchangers 5-55 Consult with manufacturer Invasive Species 40-70 For larva removal Membrane Protection 70-300 Coal Ash 20-50 depends on process treatment train

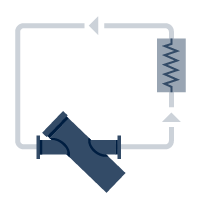

Heat Exchanger Protection

The process heat generated in industry is usually dissipated with plate and tube or plate and frame heat exchangers. Debris and scale can quickly reduce the efficiency of a heat exchanger. If neglected too long, the water treatment system will have to be shut down and the heat exchanger cleaned if it becomes too clogged which prevents the heat exchanger from performing as intended. In some cases, it is not even possible to clean the heat exchanger if it becomes too fouled. This is an unnecessary result that causes companies wasted time and money.

A properly designed PEP Filtration system will provide protection to the heat exchanger and help maintain a company’s uptime. Considering that a layer of scale that measures just 1/1,000-inch-thick can reduce the heat transfer process and increase energy costs by as much as 10%. The savings along can easily justify the cost of a self-cleaning PEP Filtration system.