-

Request a quote

Request a quote -

Resource Library

Resource Library -

Micron size guide

Micron size guideApplication Recommended

Sizing ( microns)Comments Cooling Tower Bleed-off / Blowd 5-55 Closed loop filtration 5-55 Tower Basin Cleaning / Sweeper Jet 5-55 Cartridge replacement 2-55 Protection of Heat exchangers 5-55 Consult with manufacturer Invasive Species 40-70 For larva removal Membrane Protection 70-300 Coal Ash 20-50 depends on process treatment train

HVAC / Data Centers

Water plays a critical role in the heat transfer process to any commercial or industrial HVAC system.

We should know. PEP Filters helped pioneer the self-cleaning filtration solution to the HVAC industry. And since then, PEP Filters has installed thousands of filtration solutions to improve the performance of any comfort cooling process. Whether you looking to reduce chemical costs, reduce scale build up, or prevent heat exchanger fouling, PEP Filters has the right filtration solution to meet your requirements. We even have a sweeper jet basin option to keep sediment from building up in the tower basin.

-

+

Side Stream Cooling

Water plays a critical role in the heat transfer process to any commercial or industrial HVAC system.

We should know. PEP Filters helped pioneer the self-cleaning filtration solution to the HVAC industry. And since then, PEP Filters has installed thousands of filtration solutions to improve the performance of any comfort cooling process. Whether you looking to reduce chemical costs, reduce scale build up, or prevent heat exchanger fouling, PEP Filters has the right filtration solution to meet your requirements. We even have a sweeper jet basin option to keep sediment from building up in the tower basin.

Side Stream Cooling

-

+

Reclaim Recycle Filtration

Water is a finite and valuable resource. Companies invest a significant amount of money to filter it, move it around and shape it into their product needs. It only makes sense that more wastewater is cleaned up and reused throughout any commercial, industrial, municipal or energy facility.

Reclaim Recycle Filtration

-

+

Nozzle Protection

Spray nozzles come in multiple shapes and sizes and they are used in many different applications, industries and market segments. Several examples of spray nozzles use include cooling, coating, cleaning, lubricating, humidifying, dust control, fire protection and irrigation.

In order for a spray nozzle to emit the proper pressure and spray pattern, it must remain clog free. This is where PEP Filters can assist. PEP Filters offers a wide variety of manual, semi-automatic and automatic self-cleaning filtration solutions designed to keep nozzles clean and operating at peak performance.

As a general rule of thumb, one should size a filter for nozzle protection by taking the nozzle hole size and dividing the pore size by a factor of 5-7. Utilizing this sizing parameter will ensure that the spray nozzle will remain clog free and perform as intended. For example, if the nozzle diameter is 200 micron the filter should be sized for 200 micron / 5 = 40 micron.

Nozzle Protection

-

+

Closed Loop Filtration

Closed loop or chiller loop systems require filtration to maintain peak operating efficiency. While closed loop systems are not exposed to the high levels of dirt load and debris that are typically found in an open tower or condenser loop, it is still important to provide an adequate level of filtration and protection to the system.

A PEP Filter system should be installed into a chiller loop to protect the chillers, compressors, heat exchangers and other equipment from plugging and scale build up. By doing so one can rest assured that scale, corrosion, biofilm, dirt, iron oxides, and suspended solids will be removed to prevent long-term damage to the equipment.

Closed Loop Filtration

-

+

Heat Exchanger Protection

The process heat generated in industry is usually dissipated with plate and tube or plate and frame heat exchangers. Debris and scale can quickly reduce the efficiency of a heat exchanger. If neglected too long, the water treatment system will have to be shut down and the heat exchanger cleaned if it becomes too clogged which prevents the heat exchanger from performing as intended. In some cases, it is not even possible to clean the heat exchanger if it becomes too fouled. This is an unnecessary result that causes companies wasted time and money.

A properly designed PEP Filtration system will provide protection to the heat exchanger and help maintain a company’s uptime. Considering that a layer of scale that measures just 1/1,000-inch-thick can reduce the heat transfer process and increase energy costs by as much as 10%. The savings along can easily justify the cost of a self-cleaning PEP Filtration system.

Heat Exchanger Protection

-

+

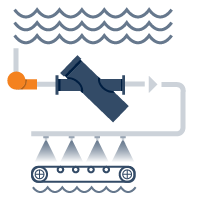

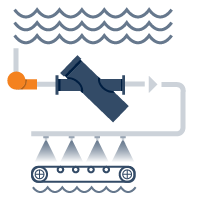

Sweeper Basin Filtration

Every cooling tower has a tower basin full of water underneath the tower assembly. The tower basin design is generally open to atmospheric conditions. Over time, debris will accumulate within the tower basin which will eventually affect the performance of the tower, water chemistry and lead to the eventual fouling of downstream equipment. If left unchecked, the basin will fill with sand, silt and other debris making it very difficult, tedious and expensive to remove.

PEP Filters Sweeper Jet system is designed to keep dirt and debris from settling out into the tower basin. Multiple nozzles are positioned around the tower basin to direct suspended solids to the intake of the PEP side stream filtration system. The filtration system then removes the solids keeping the cooling tower system free from damaging suspended solids and thus maximizes the performance of the cooling tower.

It is recommended that the PEP Filters Sweeper Jet System be designed into all new cooling tower filtration systems. It should also be retrofit into existing legacy cooling tower basins that were not originally designed with a sweeper jet system. The nozzles and optional pump assembly skid can be incorporated into other manufacturers side stream filter designed systems as well.

Sweeper Basin Filtration

-

+

Make-up Water Filtration

Many industrial processes require make up water to compensate for losses caused by evaporation, overspray and leakage. Cooling towers represent a common example where makeup water is required to replace water lost due to evaporation, drift and blowdown. Make up water can come from the city, municipality, river, lake or well. No matter the water source Make up filters help to ensure clean water is being utilized to protect equipment and reduce maintenance costs. PEP Filters is also very effective at providing protection from invasive species such as zebra and quagga mussels.

Make-up Water Filtration

-

+

Intake Water Filtration

Intake filters are designed to do the heavy lifting of large or fine solids removal from an incoming water stream so that other polishing post filtration technologies can operate more efficiently and at less cost. Intake water can come from the city, municipality, river, lake or well.

Intake Water Filtration