-

Request a quote

Request a quote -

Resource Library

Resource Library -

Micron size guide

Micron size guideApplication Recommended

Sizing ( microns)Comments Cooling Tower Bleed-off / Blowd 5-55 Closed loop filtration 5-55 Tower Basin Cleaning / Sweeper Jet 5-55 Cartridge replacement 2-55 Protection of Heat exchangers 5-55 Consult with manufacturer Invasive Species 40-70 For larva removal Membrane Protection 70-300 Coal Ash 20-50 depends on process treatment train

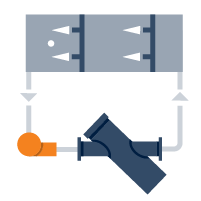

Sweeper Basin Filtration

Every cooling tower has a tower basin full of water underneath the tower assembly. The tower basin design is generally open to atmospheric conditions. Over time, debris will accumulate within the tower basin which will eventually affect the performance of the tower, water chemistry and lead to the eventual fouling of downstream equipment. If left unchecked, the basin will fill with sand, silt and other debris making it very difficult, tedious and expensive to remove.

PEP Filters Sweeper Jet system is designed to keep dirt and debris from settling out into the tower basin. Multiple nozzles are positioned around the tower basin to direct suspended solids to the intake of the PEP side stream filtration system. The filtration system then removes the solids keeping the cooling tower system free from damaging suspended solids and thus maximizes the performance of the cooling tower.

It is recommended that the PEP Filters Sweeper Jet System be designed into all new cooling tower filtration systems. It should also be retrofit into existing legacy cooling tower basins that were not originally designed with a sweeper jet system. The nozzles and optional pump assembly skid can be incorporated into other manufacturers side stream filter designed systems as well.