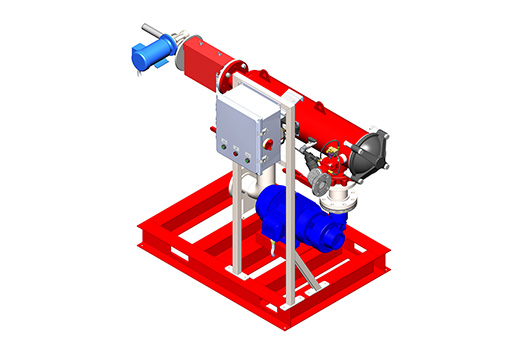

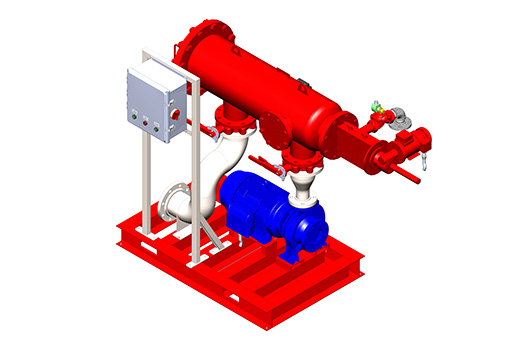

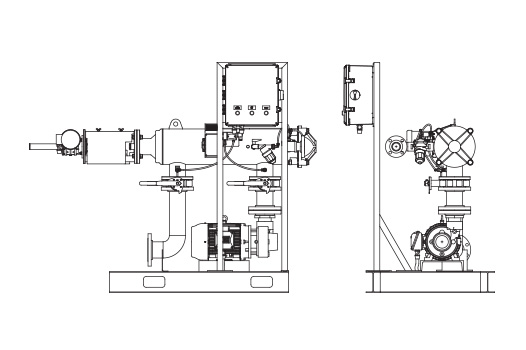

| Components |

Standard Design |

| Filter Vessel |

Epoxy coated carbon steel, 150 PSIG |

| Filter Screen |

316L stainless steel, woven mesh |

| Backwash Initiation |

Automatic (24 hour/7 day clock, differential pressure switch and manual push button) |

| Backwash Source |

Tower/system water |

| Backwash Duration |

SAF-3000: 20 seconds @ 48 gpm, SAF-4500: 20 seconds @ 66 gpm, SAF-6000: 40 seconds @ 110 gpm |

| Face Piping |

304 stainless steel |

| Pump/Motor |

System matched centrifugal pump with close-coupled TEFC motor |

| Isolation Valves |

Lever operated butterfly valves |

| Flush valve |

Hydraulically actuated diaphragm |

| Electrical Controls |

NEMA 4X thermoplastic UL-labeled control panel with lockable UV-resistant clear access cover, main power disconnect switch, overload protection, pump motor starter and control voltage transformer |

| Supply Power |

460VAC, 3-PH, 60 Hz |

| Base/Skid |

Fully skid-mounted on epoxy coated I-beam base |

| Warranty |

1 year against defects in materials and workmanship |

Request a quote

Request a quote Resource Library

Resource Library Micron size guide

Micron size guide